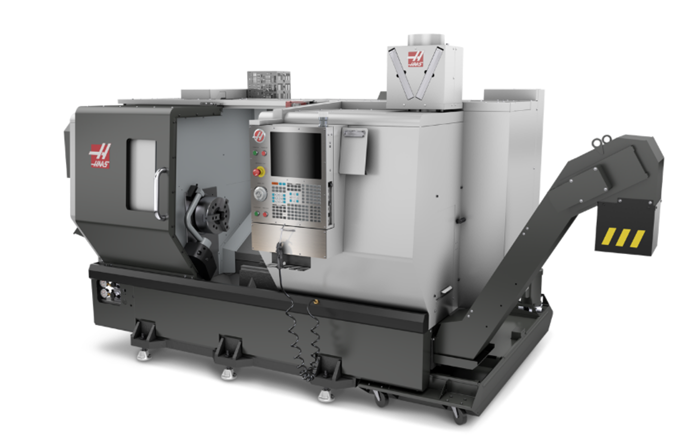

Haas ST-20Y

The Haas ST Series high-performance turning centers were designed from the ground up to provide setup flexibility, extreme rigidity, and high thermal stability.

The Haas ST Series high-performance turning centers were designed from the ground up to provide setup flexibility, extreme rigidity, and high thermal stability.

The ST-20Y has a small footprint, yet provides a generous work envelope. The addition of Y-axis and live tooling allows milling, drilling, and tapping for increased machine capabilities. This machine offers the best performance for the money – the best value – in its class.

- 12-station base mount turret (BMT65)

- Y-axis milling, drilling, and tapping

- Small footprint

- Made in the USA

Milling

- Fanuc Robo Drill T21iFL W/Pallet Changer

- Mazak Nexus VCN-570C W/Smooth Technology

- 2 MAZAK Nexus 510C

- 2 HAAS VF2 SSYT equipped with 5-axis trunnions

- HASS VF4 SS

- HASS vf2 equipped with HAAS Rotary 4th Axis Indexer

- HAAS VF-3

- TRAK DPM AGE Three Axis Bed

- Lagun FTV-2 with Protrak MX3 Control

- Kitagawa Rotary Table

Turning

- Mazak Nexus 250-II Quick Turn

- HASS ST20Y Lathe With 3rd axis

- Add new manual lathe and remove the two we don’t have anymore

- CNC Lathe with Prototrak LX2 Control (17″ swing x 48″)

- PHOENIX 216-162 Helmel Coordinate Measuring Machine Measuring Range (20”x16”x16”)

X 20” Accuracy .00008” y 16” Accuacy .00012” Z: 16” Accuracy .00012”

Repeatability .00013” Volumetric Accuracy .00038”

- Helmel Coordinate Measuring Machine (25″ x 24″ x 18″)

- 14″ Optical Comparator with metrology display inspection

- 24″ Mitutoyo Electronic Vertical Gauge System

- Full Complement of Pin Gauges and Measuring Accessories for any type of part

Computer Equipment

- CAD/CAM: MasterCAM Version 2024 for CNC programming Milling and Turning and interfacing with customer SLDPRT, step and other forms of 3 d files.

- Local Computer Network: Shop networked to all machining centers for job processing with minimum set up time.

Supplemental Equipment

- Drill Presses

- Vertical Band Saws

- WF Wells Horizontal Band Saw

- Kalamazoo Precision Cold Cut Saw

- Abrasive Cut-off Saw

- Glass Bead/Sand Blaster

- Sweeco Vibratory Finishing System

- Heat Treating Oven (9″ x 9″ x 12″)

- Surface Grinder (6″ x 18″)

Inspection

- Helmel Coordinate Measuring Machine (25″ x 24″ x 18″)

- 14″ Optical Comparator with metrology display inspection

- 24″ Mitutoyo Electronic Vertical Gauge System

- Rockwell Hardness Tester

- Bendix Profilometer for Surface Micro-finish

- Full Complement of Gauges and Accessories

All parts are inspected to meet drawing tolerances and specifications. All equipment maintained under current calibration.